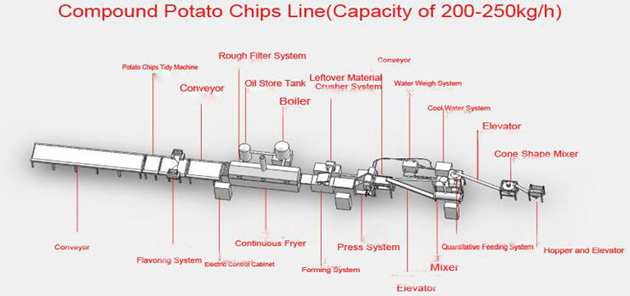

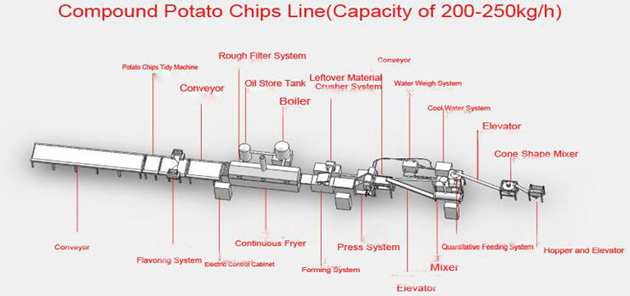

As a potato chips production line manufacturer, we can produce fresh potato chips production line and

compound potato chips production line.Now let's introduce the compound potato chips manufacturing process.

1. because the processing of compound potato chips is intermittent, it is necessary to ensure the consistency of each ingredient and the accuracy of each ingredient calculation. Dry ingredients and liquid ingredients are pre-configured and then mixed for second times. The configuration of dry ingredients and liquid raw materials can use common gauges, while secondary mixing should use dedicated gauges, then be more accurate and convenient.Dry mix ingredients are processed in a high-speed pre-mixing facility and must have a non-uniform composition below 2%. In addition to the uniform mixing of the liquid ingredients, gelatinization is also required.

2. Tableting process requirements are that the potato chips must have a uniform quality, light-textured, and elastic stable. In order to meet these requirements, it is best to do it all at once, at most twice. Because the pressure will cause moisture get into the chips, changing the characteristics of the chips, the chips organization becomes more compact, so that the external surface water can not easily leave, will produce large bubbles when fried, and potato chips is not crisp.

3. Forming process: When the potato chips is dragged by the conveyor belt and passes through the middle of the two forming rolls, the cutting machine will cut the chips into potato chips and scrap. The chips must be guaranteed to be transferred to the next process in an orderly manner from its original position.

4. Frying process: The deep-fried mesh belt is divided into upper and lower layers independently and simultaneously. When two mesh belts are combined, an arched cavity is formed to ensure that the potato chips obtain the shape of the arched potato chips during frying, and the frying temperature is controlled at 170-185 degrees Celsius generally, the production process should maintain the oil temperature, frying time is 15-20s. In order to obtain high-quality compound potato chips, the filtration treatment of oil is very important, and the recovery of volatile oil must also be considered.

5. Seasoning process: seasonings are pre-deployed powdered materials, commonly used monosodium glutamate, pepper powder, chili powder, onion powder, etc., require potato chips at a certain temperature evenly coated to the outer surface of potato chips .

6. Finishing process: After seasoning, the finished product is in a chaotic state. The finishing process is to rearrange the finished products in a certain orientation into rows and cool them to room temperature during transportation.

The above is the processing of compound potato chips. If you are interested in the

compound potato chips production line, please contact us. We are very happy to serve you.

Email:sherry@machinehall.com

skype:live:machinehall.sale

phone/whatsapp:+8618539931566